| Sign In | Join Free | My ledscreensign.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ledscreensign.com |

|

Brand Name : Hanpu

Place of Origin : China

Certification : ce,iso

MOQ : 1set

Price : 100000

Packaging Details : Packing in wooden case

Delivery Time : 90days-150days

Model Number : MVR

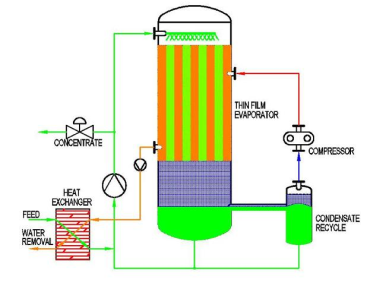

Engineer-to-order MVR (Mechanical Vapor Recompression) evaporator optimized for chemical processing and environmental protection/ZLD. The system features customized pressure setpoints (vacuum levels and compression ratios) to match product thermal limits, fouling tendencies, and regulatory discharge targets—delivering high energy efficiency, stable quality, and predictable OPEX.

Secondary vapor is mechanically compressed to raise saturation temperature and reused as the heating medium. Pressure setpoints (evaporator shell vacuum and compressor discharge) define the operating ΔT/LMTD, enabling low-temperature evaporation for heat-sensitive feeds or higher-rate modes for robust duties.

Closed-loop regulation of level, pressure, ΔT, and conductivity; interlocks for compressor/VFD, vacuum/NCG handling, condensate quality guard, and overload protection. Power-quality mitigation (AFE/filters) available per site codes.

Wetted parts in SS316L/duplex (Ti/Hastelloy on request), drainable layouts, anti-scale dosing, and validated CIP for long campaigns. Surface finishes and elastomers selectable for chemical/environmental duties.

| Parameter | Typical Range* |

|---|---|

| Operation | Continuous, 24/7 |

| Shell pressure (vacuum) | ~6–25 kPa(abs) typical (duty-dependent) |

| Compressor discharge pressure | ~45–120 kPa(abs) typical (sets ΔT and capacity) |

| Electric use (MVR) | ~15–40 kWh per ton of water evaporated |

| Fresh steam demand | Very low after start-up (backup/ancillary only) |

| Turndown | 50–100% with stable ΔT and quality |

| Availability | ≥95–98% with redundancy and planned CIP |

| Materials | SS316L / duplex; Ti/Hastelloy on request |

*Actual performance depends on feed characteristics, viscosity/fouling tendency, compression ratio, and heat-transfer design.

Yes. We engineer compressor CR, VFD range, and exchanger area to hit the target shell vacuum and discharge pressure.

By tuning discharge pressure/ΔT and circulation rate; recipes allow low-temperature quality mode or high-throughput mode.

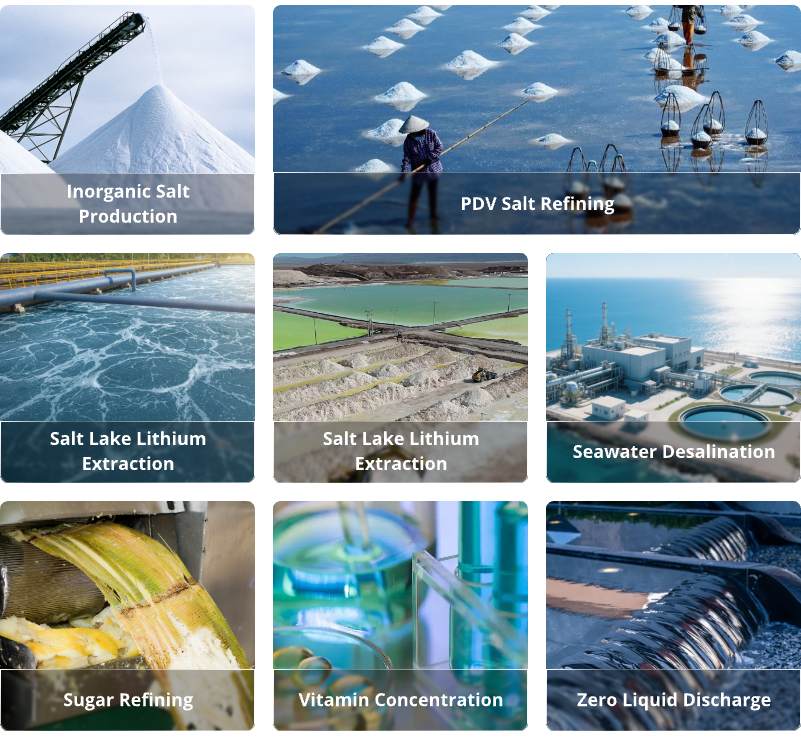

Absolutely—options include anti-scale dosing, forced-circulation crystallizer, and solid handling for ZLD compliance.

|

|

Efficient MVR Evaporator For Chemical/Environmental Protection With Customized Pressure Images |