| Sign In | Join Free | My ledscreensign.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My ledscreensign.com |

|

Brand Name : Hanpu

Model Number : MVR

Certification : CE ISO

Place of Origin : China

MOQ : 1set

Price : USD180,000-USD650,000

Supply Ability : 1sets per 3 months

Delivery Time : 120days

Packaging Details : Pallet or Wooden case

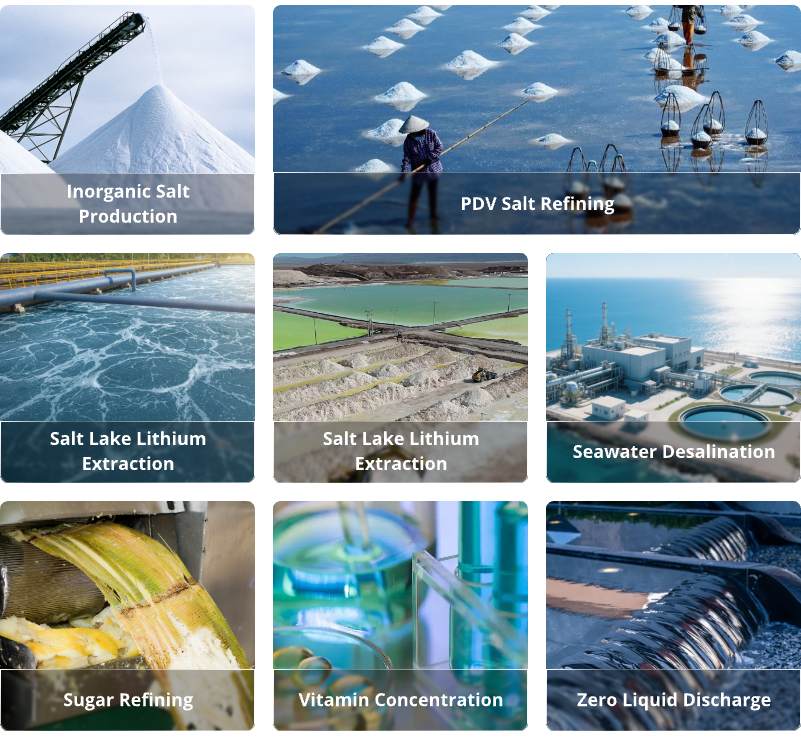

A stainless-steel MVR (Mechanical Vapor Recompression) evaporator integrated with an OSLO (draft-tube baffle) crystallizer, engineered for NaCl brine concentration and crystal growth at a nominal 5 t/h water removal. Recompressing secondary vapor as the heating medium delivers low OPEX, stable supersaturation, and consistent salt quality for edible and industrial grades.

Purified brine is evaporated under vacuum; the MVR compressor raises vapor temperature and recycles latent heat. The OSLO crystallizer operates at controlled slurry density and residence time to stabilize supersaturation and crystal growth while keeping specific energy consumption low.

Wetted parts in SS316L (duplex/SS2205 or titanium available). Drainable layouts, smooth finishes, and validated CIP support edible salt production and robust industrial service.

| Parameter | Typical Target / Range* |

|---|---|

| Evaporation rate | 5 t/h (water removal), adjustable via compressor VFD |

| Operating mode | Vacuum, continuous |

| NaCl purity (dry) | ≥ 99.2% (up to 99.7% with enhanced purification) |

| Crystal size bands | Fine 0.2–0.5 mm; Table 0.5–1.2 mm; Coarse 1.2–2.5 mm |

| Electric use (MVR) | ~15–40 kWh per ton H₂O evaporated (duty/CR dependent) |

| Fresh steam demand | Very low after start-up (backup/ancillary only) |

| Materials | SS316L wetted; duplex/SS2205 or Ti optional |

*Performance depends on brine composition, scaling tendency, compression ratio, and crystallizer design.

OSLO’s draft-tube circulation supports growth of larger, uniform crystals with low fines, improving centrifuging and drying.

Yes—with proper brine purification, hygienic finishes, and iodization/anti-caking dosing, edible-grade specs are achievable.

Softening and filtration upstream, optimized ΔT/velocity, antiscalant dosing, and scheduled CIP maintain heat-transfer rates.

|

|

5T/H Stainless Steel MVR Evaporator Oslo Crystallizer Used In NaCl Indutries Images |